The Olympia and Athena Jacket - Interfacings / Part 7

Interfacing and stabilizers are typically used between two layers of fabric in apparel and accessories. Stabilizers structure projects like tote bags and crafts, whereas interfacing is generally used to provide more body in apparel projects like shirt collars and facings.

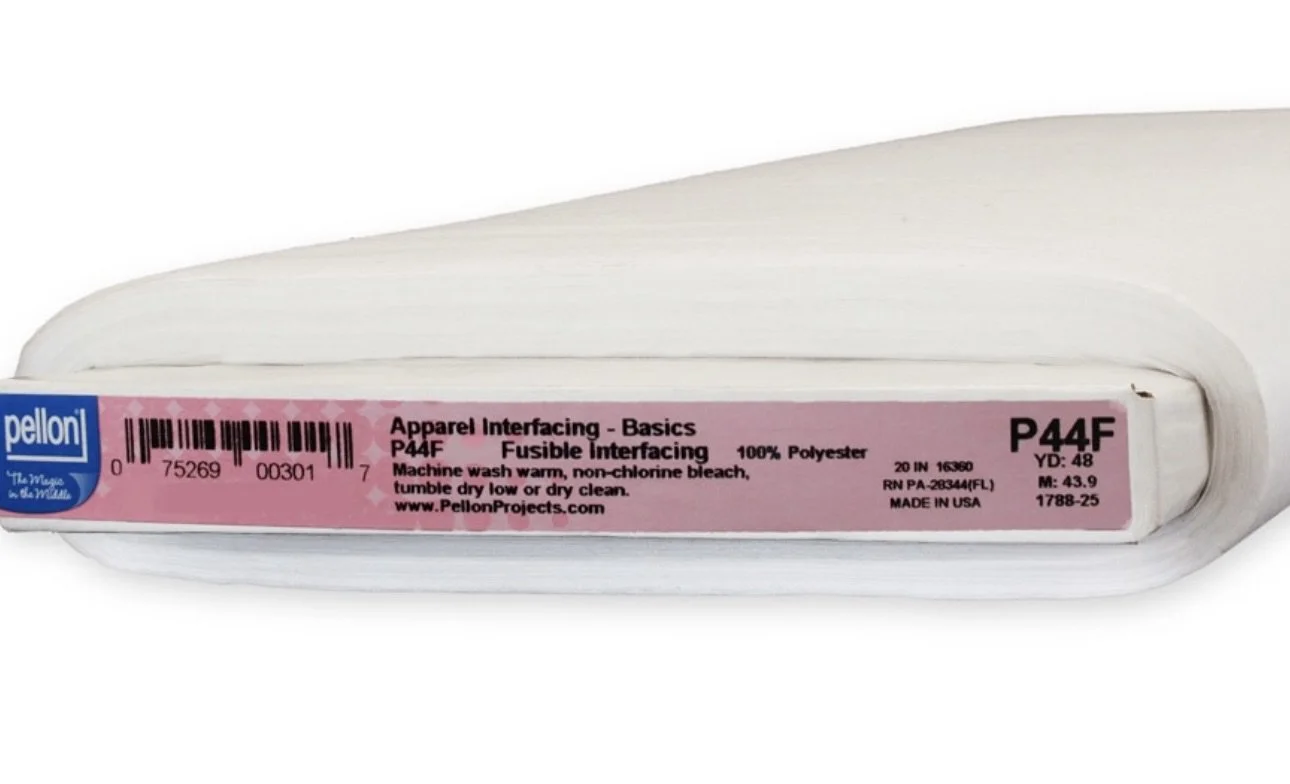

Iron-on interfacing, also known as fusible interfacing, is a fabric-like material that's attached to the inside of garments and other sewing projects to add structure and stability:

How it works

Iron-on interfacing has a layer of glue dots on one side that melts when ironed onto the fabric, permanently bonding the two together.

Where to use it

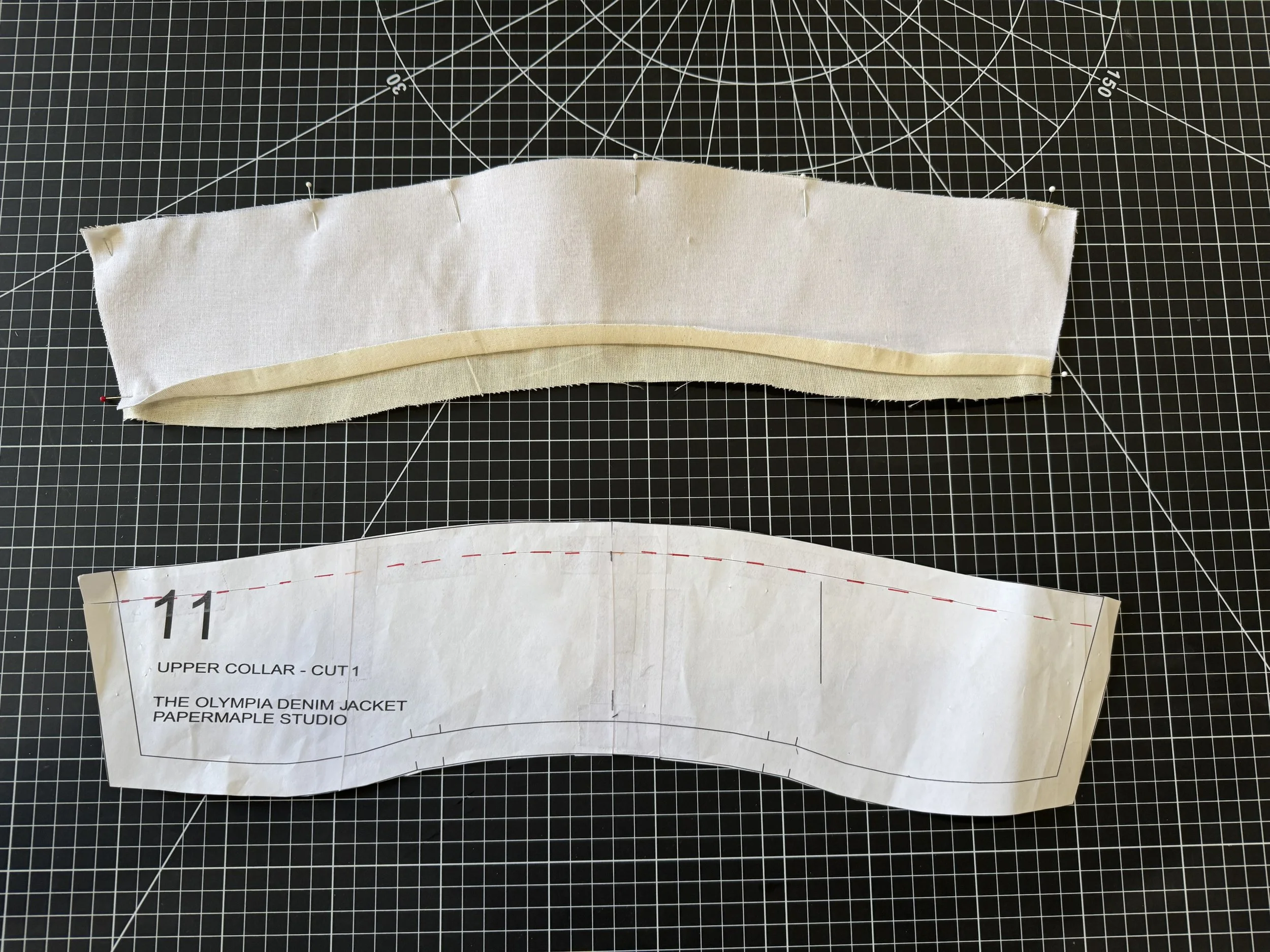

Iron-on interfacing is often used in areas like collars, cuffs, waistbands, pockets, shoulder seams, and necklines.

How to use it

To apply iron-on interfacing, place the fabric on an ironing board with the wrong side facing up, then position the interfacing on top with the glue side facing down. Gently press down with a hot, dry iron for a few seconds.

Choosing the right weight

When choosing an iron-on interfacing, look for one that's the same weight as or slightly lighter than the fabric you're attaching it to. Iron-on interfacing will become stiffer after pressing.

There's also a type of interfacing called sew-in interfacing, which is sewn onto the fabric and held in place with stitches. Sew-in interfacing is better suited for fabrics with a loose or open weave.

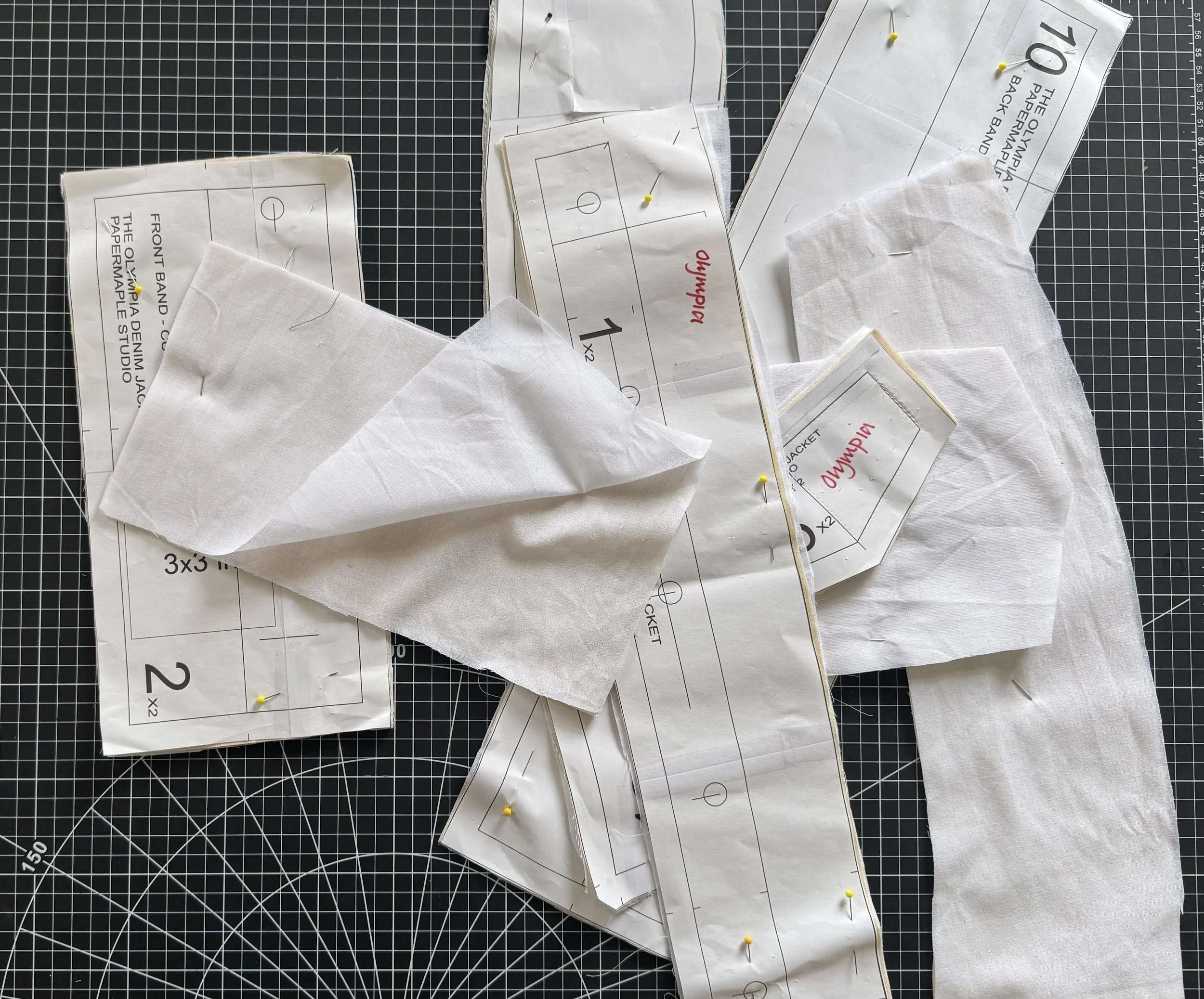

For the muslin tests, denim and twill jackets, we used a lightweight stabilizer in the studio.

It helped give crispness and clean edges, without changing the feel or drape of each fabric.